“Elinsa is your partner in thermoplastics transformation processes”

In Elinsa (Elementos Inyectados, S.A.), we have been working for more than 40 years in plastic injection moulding through a whole process of design and advice, manufacture and additional process steps to meet specifications in order to obtain the approval of the product for serial production.

Integral Solution

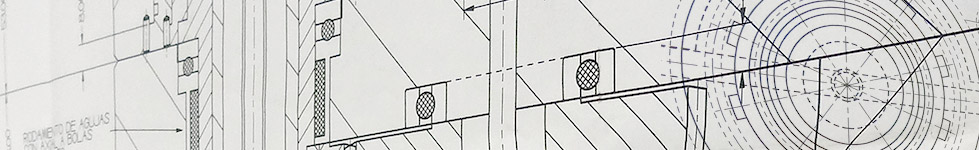

Design

Our project department creates the design of the plastic part based on a prototype,

a layout or just an idea.

The design keeps in mind different features of the plastic part, like its purpose,

durability, standard and legal specifications and aesthetic finish.

Plastic moulding

Once the mould is completely finished is taken to the plastic injection machines for serial production.

We have leading-edge injection machines, with capacity of 40 up to 300 tons of closing, completely computerized.

The raw material feeding is done with a mechanized system with mixed, dehumidification and drying treatments. We also have robotic systems for high-speed serial processes.

Materials

Thanks to our experience and knowledge through these 40 years, we have been able to accomplish projects with many different plastic materials: ABS (acrylonitrile butadiene styrene), PS (polystyrene), PP (polypropylene), PBT (polybutylene terephthalate), PC (propylene carbonate), Nylon/PA 6-66 (polyamide), PVC (polyvinyl chloride), PE (polyethylene), SAN (styrene acrylonitrile), acetal.

Assembly and Special Finishes

If your project needs assembly we can provide you this service. We also can provide other services for the final product like painting, screen printing or chroming, done by highest expertise partners.

Storage and Logistics

To finish the whole process, the plastic parts are packaged and protected to ensure conservation throughout storage and transportation. We have a stock control system with detailed information that guarantees our commitment.